Metal fiber burners are innovative heating technologies that are designed to save energy. Unlike traditional combustion methods, metal fiber burners use a unique Fecralloy fiber mesh that allows them to produce more heat energy for every unit of fuel used.

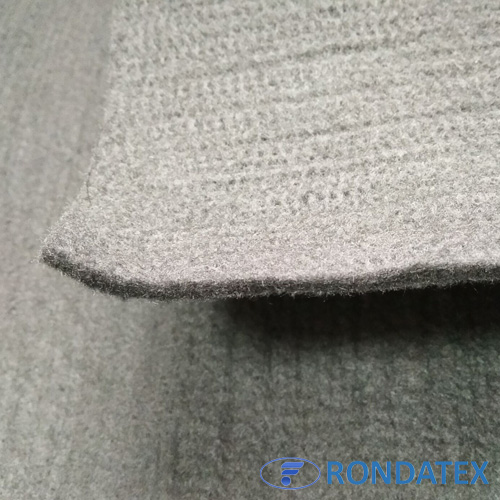

The burner is composed of thousands of intertwined metal fibers, which create an intricate Fecralloy metal fiber mesh that serves as a porous surface through which fuel passes. When fuel is ignited, it causes a flame to propagate on the surface of the metal fiber mat. The flame then radiates infrared energy that is directed towards the target surface.

The infrared energy produced by the metal fiber burner is of a different wavelength than the energy produced by traditional combustion methods. This difference in wavelength makes the energy more efficient and less wasteful. The energy produced by infrared radiation is absorbed by the target surface, rather than being lost through convection or conduction. This means that less energy is required overall to heat a given space.

Compared to traditional burners, metal fiber burners also have a much more complete combustion process. This means that more of the fuel is utilized and burned, reducing the amount of unburned fuel that is wasted. As a result, metal fiber burners are able to achieve higher combustion efficiencies, which translates into fuel cost savings.

Overall, metal fiber burners are an energy-efficient alternative to traditional combustion methods, such as red infrared burners. Thanks to their unique design and advanced combustion process, metal fiber burners are able to produce more heat energy while using less fuel, making them an ideal choice for a wide range of applications.

Rondatex is professional supplier of Fecralloy metal fiber mesh for infrared metal fiber gas burners.the featured products include woven Fecralloy metal fiber mesh, knitted Fecralloy mesh and Fecralloy metal fiber felt.we look forward to cooperating with you on the area.

Email

Email Tel/Wechat

Tel/Wechat

Home

Home Tel

Tel Products

Products