The infrared radiation burner can absorb the amount of air used for combustion at one time. The gas and the inhaled air diffuse and gradually mix in the mixing section of the ejector due to their different speed, concentration and specific gravity.

When the gas evenly flows into the head of the radiator, it will burn when it meets the ignition source on the head surface of the radiator, and the final combustion surface will show a hot red color. At this time, the surface temperature will reach 800-900 C degrees, and the combustion area will reach 1100-1400 C degrees, thus radiating the infrared ray with a wavelength of 2-4 microns.

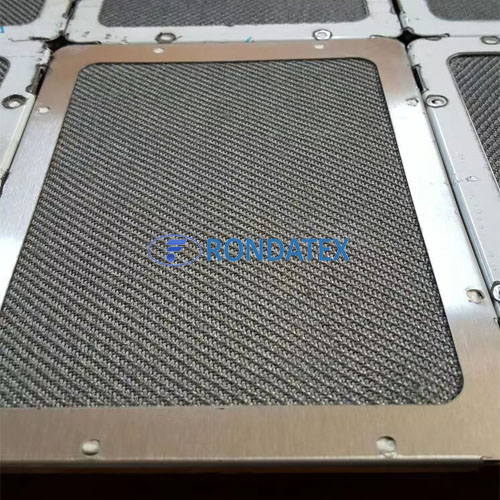

The metal fiber burner uses FeCrAl alloy metal fiber to generate infrared radiation heat source with high efficiency heat conduction. The main body of the metal fiber burner is made of stainless steel, and the internal part is a gas diversion baffle, which can be equipped with water cooling function to resist overheating and mechanical vibration.

RONDATEX specializes in providing Fecralloy metal fiber mesh, which can be used for infrared radiation burner and blue flame burner. The material has been verified by the market for many years, which can ensure the use quality.

Email

Email Tel/Wechat

Tel/Wechat

Home

Home Tel

Tel Products

Products