[Specification]

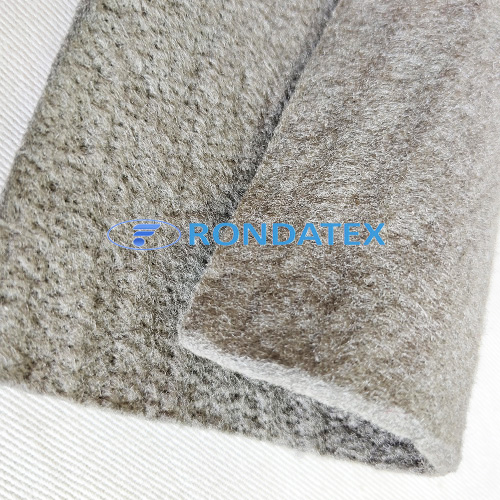

| Material | 100% 316L stainless steel fiber |

| Thickness | 5mm |

| Weight | 1600g/m2 |

[Application]

Stainless steel fiber felt is needled of 316L stainless steel fiber,it has various applications, including:

1. High-temperature filtration: Stainless steel fiber needle felt can withstand high temperatures, making it suitable for use in high-temperature filtration applications, such as in the metal processing industry.

2. Chemical filtration: Stainless steel fiber needle felt is resistant to chemicals, making it ideal for use in chemical filtration applications, such as in the petrochemical industry.

3. Dust collection: Stainless steel fiber needled felt is effective in trapping fine particles, making it useful in dust collection applications, such as in the pharmaceutical industry.

4. Electrically conductive textiles: Stainless steel fiber needle felt can be used to make electrically conductive textiles, such as in the production of electrostatic discharge (ESD) clothing.

5. Reinforcement: Stainless steel fiber needle felt can be used to reinforce materials, such as in the production of composites or in the construction industry.

6. Soundproofing: Stainless steel fiber felt has good sound absorption properties, making it useful in soundproofing applications, such as in the automotive industry.

[Application in glass making industry]

Stainless steel needle-punched felt has become an important material in the glass manufacturing process. Its unique characteristics and functions have allowed it to play a crucial role in ensuring that finished glass products are of the highest quality.

One of the main functions of stainless steel needled felt in the glass manufacturing process is in the filtration of glass melts. In order to produce high quality glass products, impurities and other foreign substances must be removed from the glass melt before it is molded. Stainless steel needle-punched felt is ideal for this job because its fibers are extremely fine and can capture impurities and other particles that would otherwise pass through other filters.

Stainless steel felt can also be used in the production of glass wool insulation and other glass fiber products. When glass wool is produced, a stream of molten glass is ejected through a fine nozzle, where it is rapidly cooled and stretched into thin fibers. These fibers are then compressed into wool-like mats. Stainless steel needle-punched felt is used as a backing material to support the thin glass fibers as they are compressed, ensuring that the resulting mats are strong and have a uniform density.

Finally, stainless steel needled felt is used as a lining material in glass tanks and furnaces. Glass manufacturing requires extremely high temperatures, and the lining of these tanks and furnaces must be able to withstand these temperatures without degrading or melting. Stainless steel needle felt provides excellent thermal stability and can withstand temperatures of up to 1000°C, making it an ideal material for use in these applications.

The use of stainless steel felt in the glass manufacturing process plays a vital role in producing high-quality glass products. Its characteristics of excellent filtration, strong support, and high thermal stability make it a valuable material for glass manufacturers worldwide. With the help of stainless steel needle-punched felt, glass manufacturing will continue to enhance its technology, increase its efficiency, and produce better products that benefit people's lives.

Email

Email Tel/Wechat

Tel/Wechat

Knitted FeCrAl Metal Fiber

Knitted FeCrAl Metal Fiber  Heat Resist Stainless Steel Fabric

Heat Resist Stainless Steel Fabric  Stainless Steel Conductive Fabric

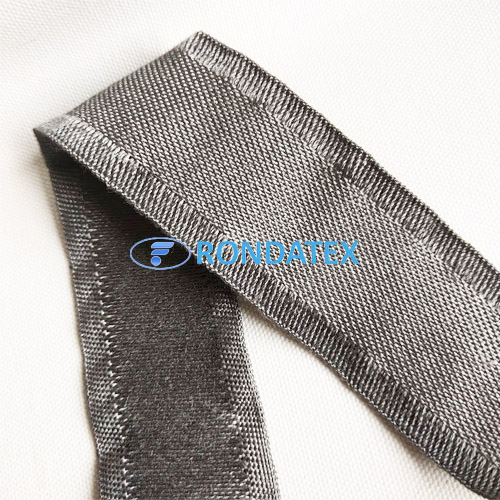

Stainless Steel Conductive Fabric  Stainless Steel Fiber Tape

Stainless Steel Fiber Tape  Fecralloy Fiber Mat For Gas Burner

Fecralloy Fiber Mat For Gas Burner

Home

Home Tel

Tel Products

Products