[Specifications]

| Model NO. | FW-60 |

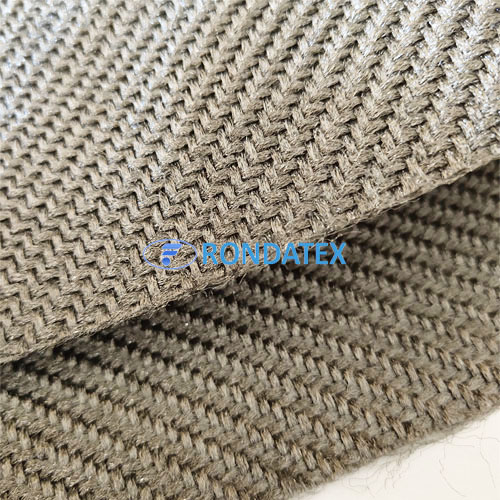

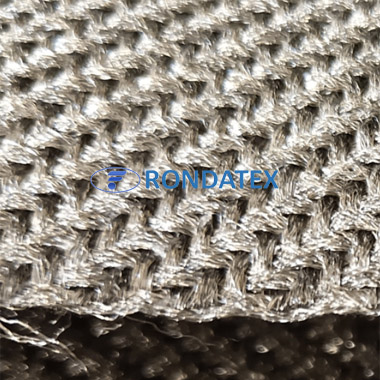

| Material | 100% Fecralloy continuous metal wire |

| Thickness | 1.6-1.8mm |

| Weight | 1700 g/m2 |

| Roll width | 100 cm, max 120cm |

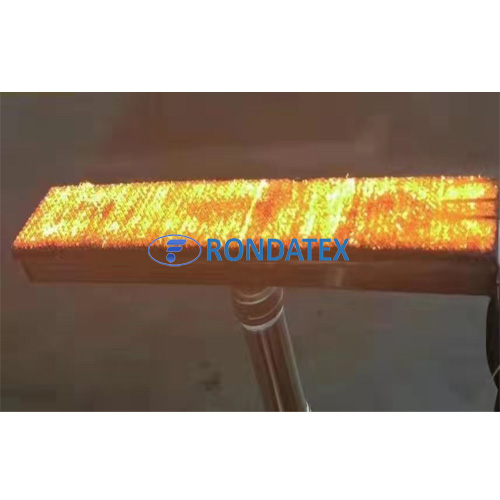

| Operating temperature | 800-1100 °C |

| Package | In carton,10m per roll |

[Product Introduction]

The FW-60 metal fiber mesh has a compact structure and uniform breathability. It is woven with continuous thick fibers, which has stronger load-bearing capacity and can work continuously at high temperatures.

FeCrAl metal fibers have become increasingly popular in infrared burners due to their numerous advantages. The metal fibers are lightweight and have high strength, making it an excellent material for use in infrared gas burners. Let's explore more about what makes these fibers the perfect material for infrared burners.

First and foremost, FeCrAl metal fibers have excellent thermal properties. They can withstand extremely high temperatures, which is critical for any material used in burners. They are also highly conductive and can transfer heat quickly, making them an ideal material for use in infrared burners.

In addition, these metal fibers have outstanding corrosion resistance and durability. They are resistant to corrosion caused by high-temperature combustion gases, making them incredibly long-lasting. This quality is essential because any material used in an infrared gas burner has to be able to withstand the rigors of heat, corrosion, and wear and tear.

Furthermore, FeCrAl metal fibers are easy to shape and mold into any design or pattern. This property makes them perfect for use in infrared burners, where precision and versatility are essential.

Finally, and most importantly, using FeCrAl fibers as a material for infrared gas burners is environmentally friendly. This material is recyclable, non-toxic, and does not emit any harmful substances into the atmosphere. This makes it a perfect material choice for organizations or individuals who are concerned about their environmental impact.

FeCrAl metal fibers have become a popular material for infrared gas burners due to their excellent thermal properties, corrosion resistance, durability, easy molding, and environmentally-friendly qualities. It is undeniable that this material has many benefits and will continue to be widely used in various industries

[Application]

Email

Email Tel/Wechat

Tel/Wechat

Knitted FeCrAl Metal Fiber

Knitted FeCrAl Metal Fiber  FeCrAl Fiber Mesh For Gas Burner

FeCrAl Fiber Mesh For Gas Burner  Metal Fiber Mat For Infrared Baking Ovens

Metal Fiber Mat For Infrared Baking Ovens  Fecralloy Metal Fiber Mat For Infrared Heater

Fecralloy Metal Fiber Mat For Infrared Heater

Home

Home Tel

Tel Products

Products