[Specifications]

Model NO. | FW-60 |

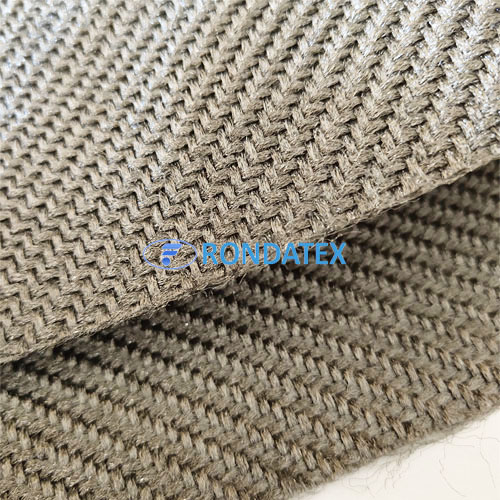

Material | 100% FeCrAl continuous thick wire |

| Thickness | 1.6mm |

| Style | Woven(impact) |

Average Weight | 1700 g/m2 |

Roll width | 100 cm, max 122cm |

Package | In carton,10m per roll . we can send cut pieces for trial orders |

Operating temperature | 600-1200 °C,max 1400 °C |

[ Introduction]

The metal fiber burner is a highly efficient device that is widely used for industrial heating applications. It consists of several components that work together to ensure efficient and safe combustion. The combustion head, in particular, is a critical component that plays a significant role in the device's performance.

The combustion head is composed of several parts, including a FeCrAl metal fiber mesh, a diffuser plate, a perforated plate, and a nozzle. The metal fiber mesh is the most crucial component that provides the primary surface area for combustion. It is made up of a special blend of metal fibers that are packed tightly together and designed to provide a high surface area-to-volume ratio.

The diffuser plate is located above the metal fiber matrix and serves to distribute the fuel mixture evenly across the surface. It also creates a uniform airflow pattern, which helps to maintain a stable flame front. The perforated plate is located below the matrix and is designed to ensure an even distribution of air across the surface of the matrix. It also helps to prevent backfire and flashback, which can cause damage to the device.

The nozzle is another critical component that ensures efficient combustion. It is designed to deliver the fuel mixture to the combustion head at a precise rate and pressure. The nozzle is also responsible for regulating the air-to-fuel ratio, which is essential for maintaining a stable and efficient flame.

The combustion head of a infrared metal fiber burner is composed of several components, including a FeCrAl metal fiber mesh, a diffuser plate, a perforated plate, and a nozzle. Together, these components ensure efficient and safe combustion by providing an even distribution of fuel and air across the surface of the matrix and regulating the air-to-fuel ratio. With its reliable performance and low emissions, the metal fiber burner is an excellent choice for industrial heating applications.

[Application]

Email

Email Tel/Wechat

Tel/Wechat

Knitted FeCrAl Metal Fiber

Knitted FeCrAl Metal Fiber  High Temp Resist FeCrAl Fabric

High Temp Resist FeCrAl Fabric  FeCrAl Metal Fiber For Gas Burner

FeCrAl Metal Fiber For Gas Burner  Fecralloy Fiber Mat For Gas Burner

Fecralloy Fiber Mat For Gas Burner

Home

Home Tel

Tel Products

Products